About Us

Helicoid Industries was founded to bring nature-inspired fiber architecture from the lab to the real world.

Backed by years of biomimicry research and leading global partnerships, our patented Helicoid™ technology delivers stronger, lighter, and more durable composites for multiple industries.

Inspired by Nature

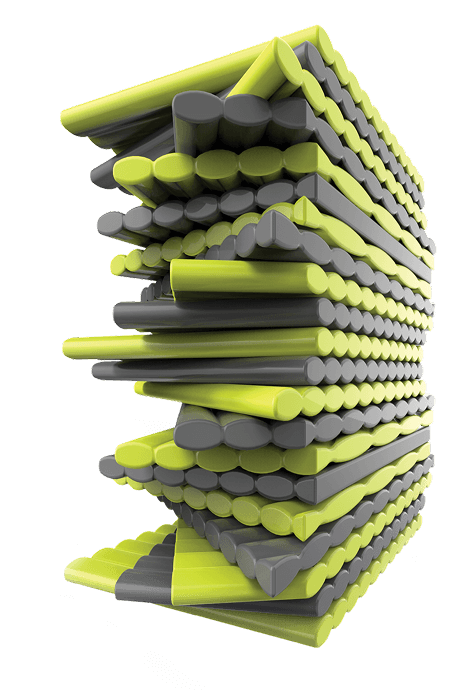

Nature evolved highly efficient structures with outstanding toughness, impact resistance, and durability.

The "smasher" mantis shrimp inspired our Helicoid™ architecture, mimicking its helicoidal layered design to dramatically improve performance in composites.

Our Technology results in

Toughness

Lighter Weight

Crack Resistence

Cost Savings

Energy Efficiency

This Helicoid™ structure is a platform technology that can easily be applied to numerous industries that are constantly searching for lighter and stronger components.

Helicoid Industries provides support and know-how to customers evaluating our technology including layup recommendations, FEA simulations and prototype testing and layup optimization. Contact us today to get started.

The Helicoid Journey

Mantis Shrimp

Millions of years ago, the Mantis Shrimp inspired an ultra-resistant fiber structure.

2019

Founded by Chad Wasllenkoff, driven by nature’s blueprint.

14+ Years

Collaboration with 16+ universities & global research leaders.

$12M+

Early groundbreaking Helicoid™ studies funded.

2020

Commercialization begins. Early industry adopters.

Advancing Sustainable Solutions

Helicoid Industries is transforming composite materials through sustainable innovation. By using less raw material and creating less waste, we help industries meet performance goals while reducing their environmental footprint. Our technology is designed to work better for people and the planet.

Eco Innovation

Developing sustainable solutions to align with modern values and market trends

Material Efficiency

Cutting raw material use improves cost and reduces environmental impact

Lifecycle Impact

Holistic approach from manufacturing to end-of-life disposal

Helicoid Industries is committed to reducing socio-environmental impacts while delivering comfort and value to consumers.

Why Material Efficiency?

Raw materials account for over 50% of production costs. By using less and wasting less, we save resources, cut expenses, and reduce environmental impact.

Impact at a Glance

- Reduced Weight

- Increased Toughness

- Improved Energy Efficiency

- Less Manufacturing Waste

Wind Turbines

Helicoid enables longer, more durable blades that resist harsh environments and reduce the cost of energy production.

Automotive

Reducing vehicle weight by just 10% can improve fuel economy by up to 8%. Helicoid makes lightweight strength possible.

Aerospace

Helicoid tech can cut aircraft weight by up to 50,000 lbs, boosting efficiency and reducing emissions at scale.