Helicoid Technology

The Inspiration –

The Mantis Shrimp

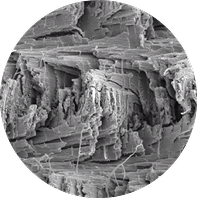

The Helicoid™ evolved over hundreds of millions of years to become highly efficient and incredibly tough.

The mantis shrimp uses a hammer-like club to deliver rapid underwater strikes strong enough to shatter shells. Its unique internal structure absorbs and withstands extreme impact forces.

- Strikes faster than a .22 caliber bullet

- Capable of pulverizing hard-shelled prey

- Internal architecture absorbs and dissipates energy

- Naturally durable and resilient

- More sustainable design principles

- Enables reduced production costs

Helicoid™ has emulated this efficient architecture.

The Helicoid™ Architecture

IT’S NOT THE MATERIAL – IT’S THE STRUCTURE

Sheets of parallel fibers are stacked, and each layer is rotated to form a Helicoid™

Helicoid™ Composite Laminate Benefits

Our Engineering Services

Laminate design & material selection

FEA simulations to optimize Helicoid™ performance

Prototyping and laboratory testing

Product and process integration of Helicoid™ architecture

Transverse deployment across multiple product categories

Access to advanced research facilities for testing, manufacturing, and materials analysis

Helicoid™ Composite Reinforcements

Helicoid™ Non-Crimp-Fabrics designed to meet diverse customer applications.

Manufacture 2D and 3D preforms in dry or prepreg states using automated placement.

Access prototyping, lab testing, and world-class facilities for manufacturing and material analysis.

From Shrimp to Product –

Nature Emulated

$14M+ invested to emulate the Helicoid™ architecture.

Patented by UCR and licensed exclusively to Helicoid™ for commercialization.